We Hear These Three Questions Every Day

Almost every first email we receive starts the same way:

“What’s your MOQ?”

“Can you send your price list?”

“How long does production take?”

These are fair questions.

But here’s the problem we see again and again:

Most buyers try to judge MOQ, price, and lead time separately.

That’s exactly where misunderstandings — and wrong sourcing decisions — begin.

In real OEM pet supplies manufacturing, these three things are tied together.

You cannot change one without affecting the other two.

This article explains how they actually work in real orders, not in theory.

Let’s Start with the Biggest Misunderstanding: MOQ

MOQ Is Not a Sales Rule — It’s a Production Limit

Many buyers think MOQ is something factories “set by policy”.

It isn’t.

MOQ exists because production has physical limits:

Machines need setup time

Materials are purchased in bulk

Workers are assigned to production lines

Below a certain quantity, production becomes:

Inefficient

Unstable

More expensive per unit

That minimum stable quantity is what MOQ really means.

Why MOQ Has Nothing to Do with “How Serious” Your Order Is

We often hear this:

“Our order value is high. Why is MOQ still an issue?”

Because MOQ is not about order value.

It’s about how the product is made.

For example:

Injection-molded dog toys

Sewn pet beds

Stainless steel bowls

Each requires:

Different machines

Different setup time

Different material purchasing methods

That’s why MOQ is product-based, not order-based.

Why Factories Can’t Offer “One Universal MOQ”

If a factory tells you:

“Our MOQ is 500 pcs for everything”

You should be cautious.

That usually means:

They are reselling, not manufacturing

Or they are ignoring production reality

A real OEM manufacturer will always say:

“MOQ depends on the product and customization.”

And that’s the honest answer.

Now Let’s Talk About Pricing — Without Marketing Language

Why Asking for “Unit Price” Alone Is Dangerous

Another common situation:

“Just tell me the unit price first.”

The issue is — unit price without quantity is meaningless in OEM manufacturing.

Here’s why.

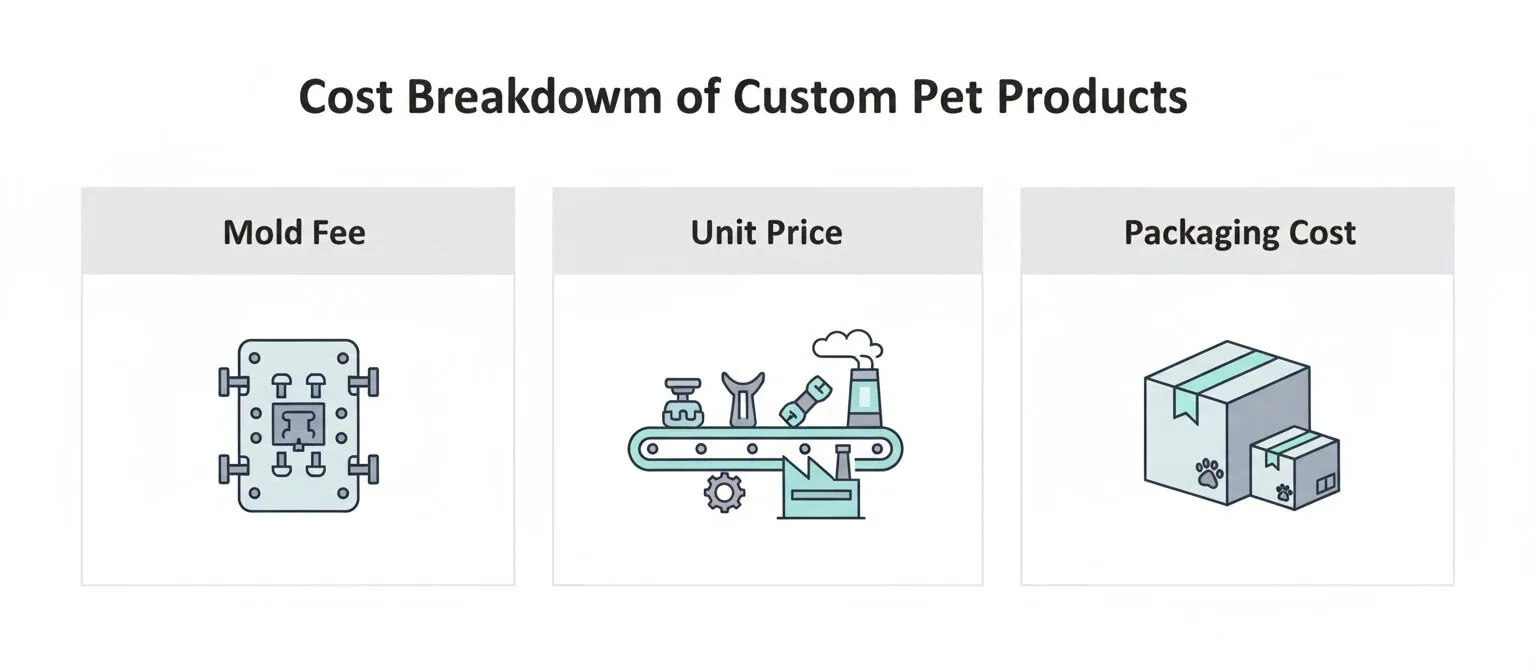

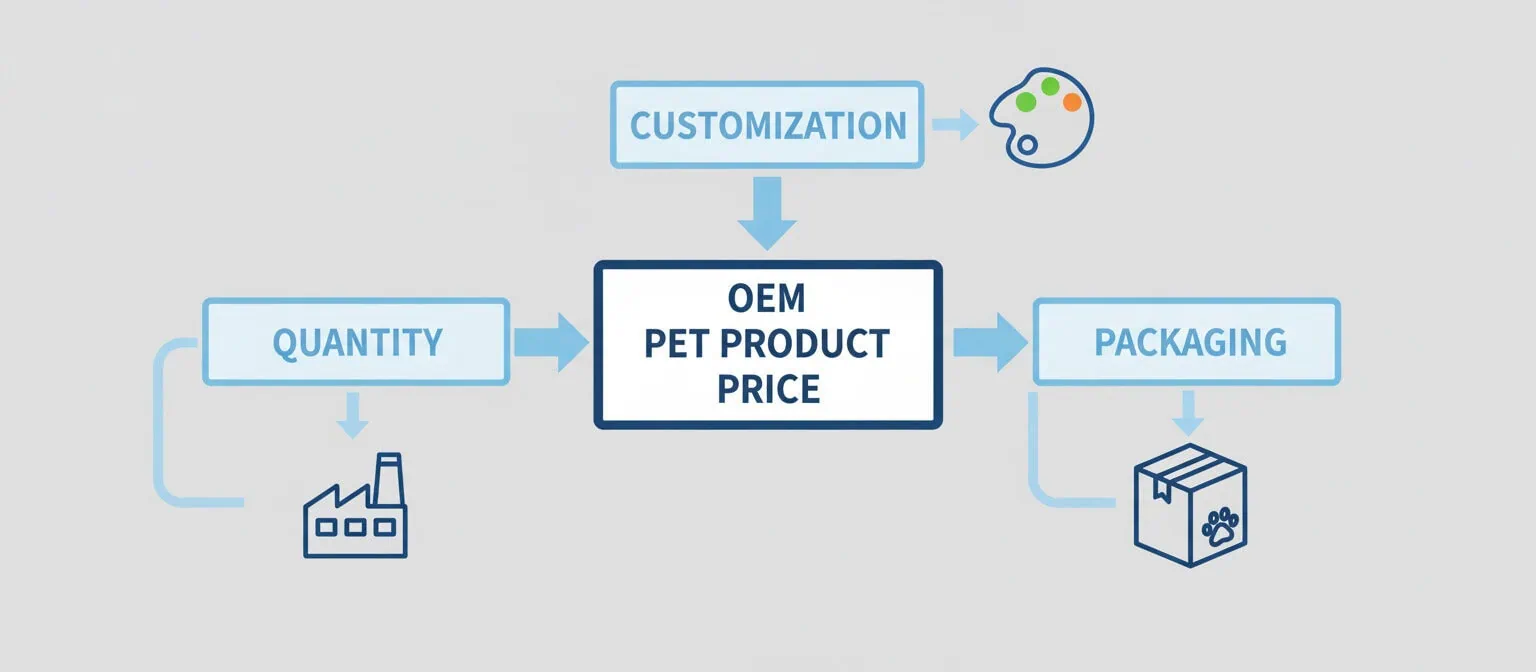

What Actually Makes Up the Price of a Pet Product

A pet product unit price usually includes:

Raw materials

Labor

Production overhead

Packaging

Quality control

Only one of these is truly fixed.

Everything else changes with:

Quantity

Customization

Packaging method

This is why pricing is always quoted in quantity tiers.

Why Larger Quantities Lower Unit Cost (It’s Not Greed)

Factories don’t lower prices because they “like big buyers more”.

Prices go down because:

Material cost per unit decreases

Setup cost is spread over more units

Production efficiency improves

This is physics and math — not negotiation tactics.

Customization: Small Changes, Real Cost Impact

From the buyer side, customization may feel “minor”:

A logo

A color change

A printed box

From the factory side, that often means:

New setup

Separate material batches

Additional QC steps

This is why customization always affects pricing, even if the product looks similar.

Lead Time: The Part Buyers Underestimate Most

Lead Time Is Not “Production Time”

This is one of the most common misunderstandings.

Buyers ask:

“How long is your production time?”

What they really need to know is:

How long until my goods are ready to ship?

These are not the same.

What Lead Time Actually Includes

A realistic lead time includes:

Sample confirmation (if required)

Tooling or setup (if needed)

Bulk production

Packaging

Final inspection

Skipping any of these steps usually creates problems later.

Why “Rush Orders” Often Cost More (or Fail)

When buyers ask for very short lead times, factories must:

Reschedule production

Run smaller batches

Increase overtime

This increases:

Cost

Risk of defects

Fast production is possible — but it must be planned early.

Seasonal Reality Most Buyers Ignore

Before major seasons (especially Q3–Q4):

Factory capacity tightens

Material lead times increase

Packaging suppliers get busy

If your product is seasonal, planning late is the biggest risk, not MOQ.

A Realistic Example (Based on Actual Orders)

Let’s look at a simplified but realistic case.

Buyer’s Situation

3 dog toy models

Custom logo

Retail packaging

Target market: EU

What Actually Happens

MOQ is checked per model, not total order

Price is calculated based on:

Quantity per SKU

Packaging type

Lead time includes:

Packaging approval

Production scheduling

When buyers understand this early:

Pricing discussions are faster

Lead times are more accurate

Orders move smoothly

How Smart Buyers Get Better Results (This Matters)

The buyers who get the best results usually do three simple things:

1. They Don’t Fixate on MOQ Alone

They look at:

Unit cost

Total landed cost

Long-term scalability

Sometimes a slightly higher MOQ actually means lower risk and lower cost per unit.

2. They Decide Packaging Early

Packaging decisions made early:

Shorten lead time

Reduce cost surprises

Packaging decisions made late:

Delay shipment

Increase cost

3. They Share Estimated Quantities Honestly

Even a range is enough.

This allows the factory to:

Recommend better options

Optimize cost

Avoid unrealistic promises

What a Good OEM Manufacturer Should Do for You

A real OEM partner should:

Explain limitations clearly

Suggest alternatives when needed

Help balance cost, MOQ, and lead time

If a supplier only says “yes” without explanation, problems usually appear later.

Final Words (From a Factory Perspective)

MOQ, pricing, and lead time are not barriers.

They are signals.

They tell you:

How a product is made

What scale is realistic

How to plan growth

Buyers who understand this:

Save time

Avoid costly mistakes

Build stable supply chains

If you are sourcing from a pet supplies manufacturer in China, the goal is not to find the lowest MOQ or fastest promise — but the most realistic plan that works in production.