Table of Contents

If you are already talking to factories about custom pet products, you’ve probably reached this moment:

You get the quotation.

You look at the numbers.

And you think:

“This is higher than I expected.”

“Where exactly is the cost coming from?”

“Is there any way to reduce it?”

This is exactly the point where good projects move forward — and bad ones get stuck.

Let me be very clear from the beginning:

Most custom pet product projects are not expensive because of the factory.

They are expensive because buyers don’t see the full cost picture early enough.

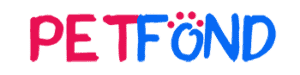

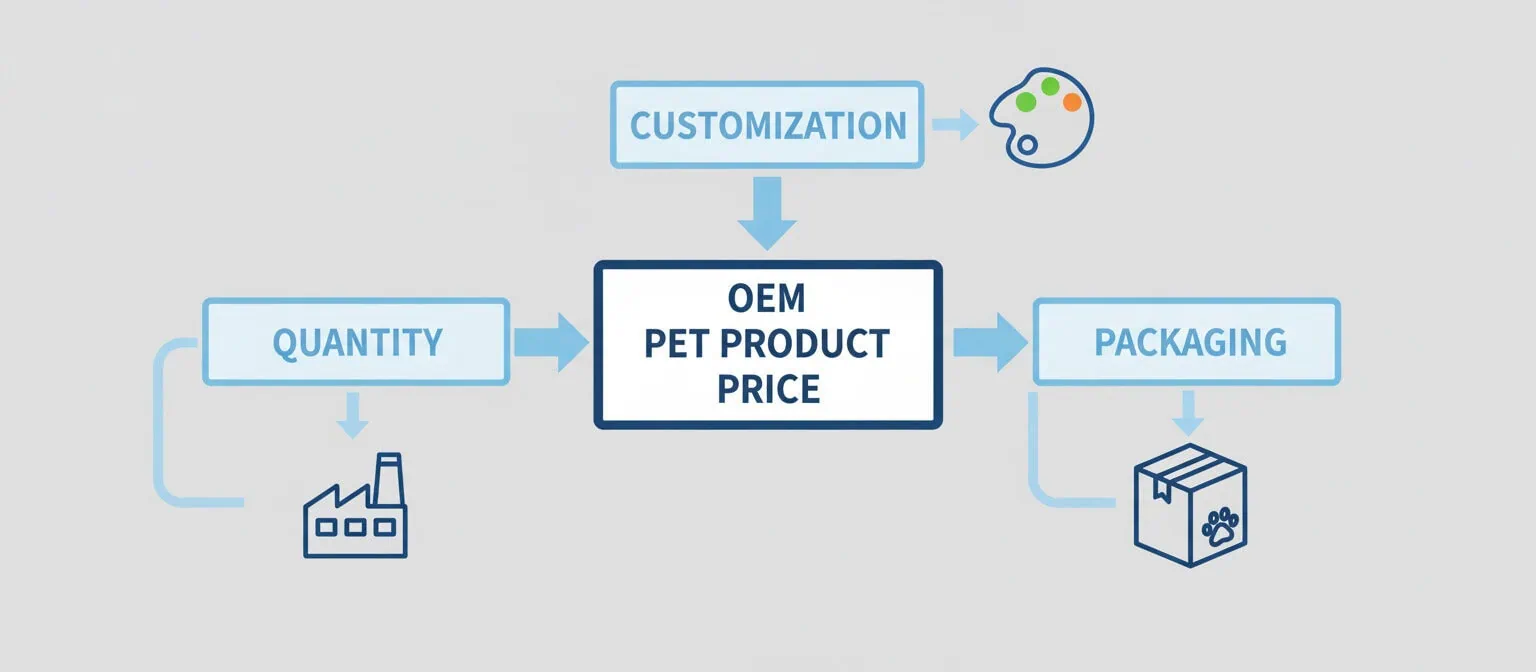

This article explains how we actually look at mold fees, unit price, and packaging cost from a factory side — and how experienced buyers use this knowledge to control cost without hurting the product.

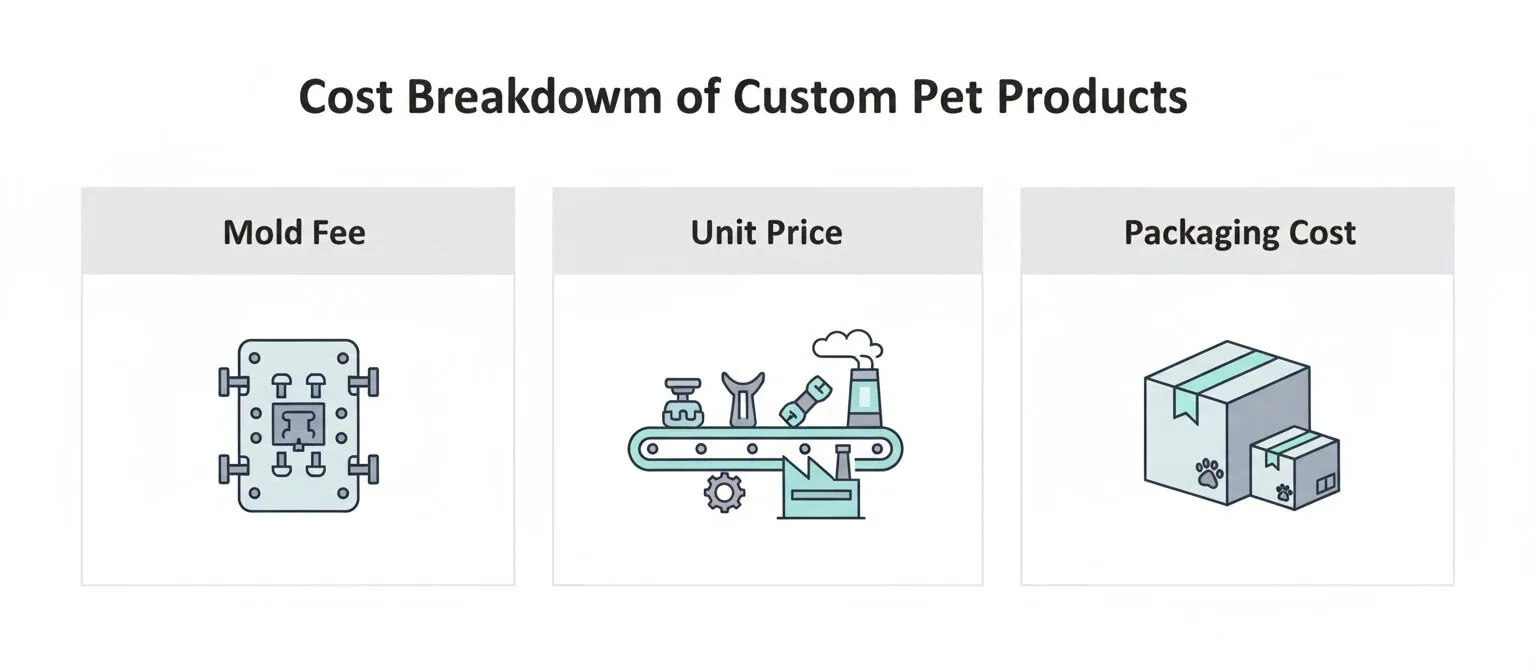

First, a Reality Check About “Custom”

When buyers say “custom”, they often mean very different things.

From a factory point of view, these are completely different projects:

Same product, new color

Same product, logo added

Same product, retail packaging

Slight structural adjustment

Fully new product design

The mistake many buyers make is assuming:

“Custom is custom — the cost difference shouldn’t be that big.”

In reality, each step up changes the cost structure.

If you understand where you are on this ladder, cost discussions become much easier.

Mold Fees: Not a Trap — Just a Gate

Let’s talk about mold fees honestly, because this is where many projects slow down.

Why factories ask for a mold fee

A mold is not a “tool fee” we add for fun.

It’s a one-time investment that determines:

Whether the product can be produced consistently

Whether quality is stable at scale

Whether defect rate stays under control

For injection-molded pet products, the mold is the product.

When you really need to pay a mold fee

You usually need a mold fee when:

The product shape is new

The structure is changed

Existing molds don’t match your design

You usually don’t need it when:

Using an existing mold

Only changing color

Adding logo printing

This is why two suppliers may quote:

One with a mold fee

One without

And both may still be “correct” — they’re just offering different levels of exclusivity.

A sales truth many factories won’t say

If you want:

Your own design

Long-term differentiation

Price protection

Then a mold fee is often worth paying.

If you are:

Testing the market

Launching your first SKU

Controlling cash flow

Then starting with an existing mold is usually smarter.

There is no “right” answer — only a right strategy.

Unit Price: The Number Everyone Wants, but No One Should Ask First

Here is something we explain to customers almost every day:

Unit price is not a starting point.

It’s a result of decisions you’ve already made.

Quantity decides more than you think

From a factory perspective:

Setup time is fixed

Labor preparation is fixed

Machines don’t care if you run 500 pcs or 5,000 pcs

That’s why:

Small quantity = higher unit cost

Larger quantity = lower unit cost

This is also why we always ask:

“What quantity are you planning?”

Not to push you — but because pricing without quantity is guessing.

Materials: cheap on paper, expensive in reality

We’ve seen many cases where buyers choose:

Slightly cheaper material

Lower grade option

And later face:

Product complaints

Returns

Brand damage

Good buyers don’t ask:

“What’s the cheapest material?”

They ask:

“What material makes sense for this market and price point?”

That question saves money long-term.

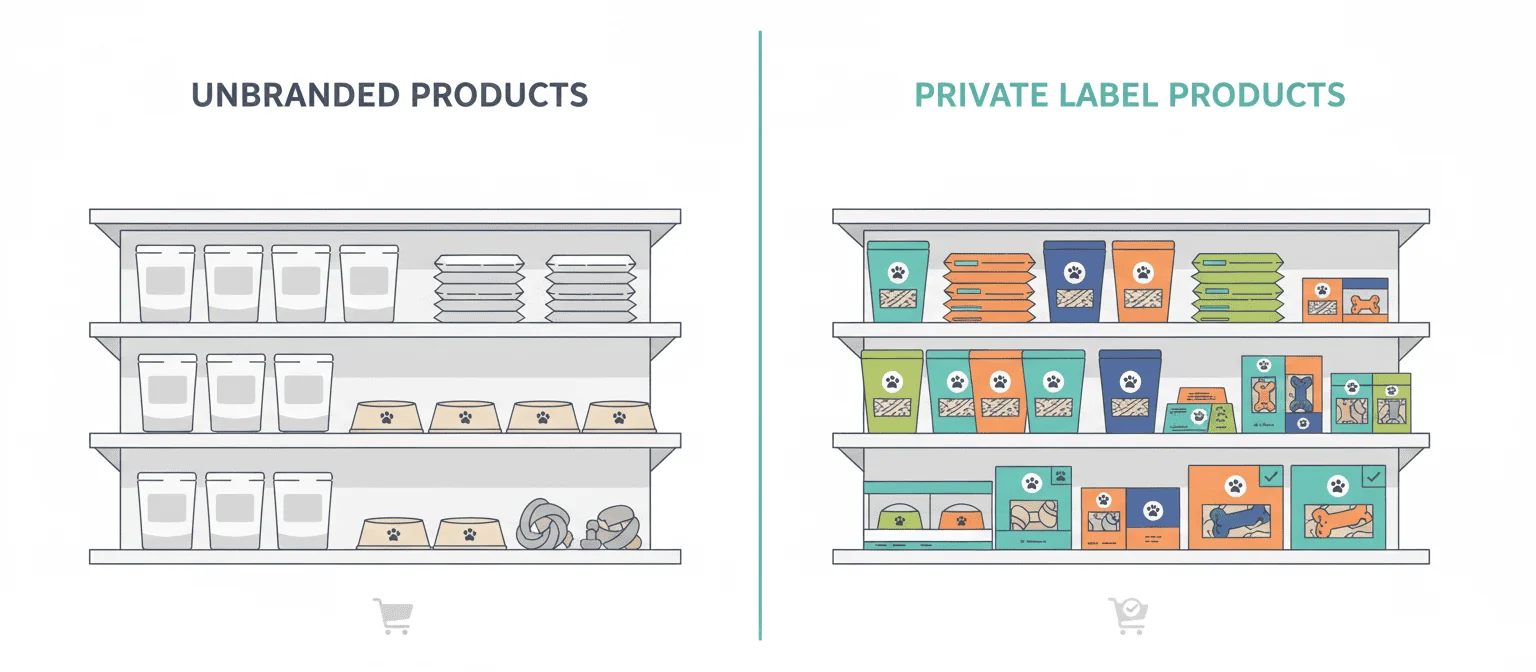

Packaging: Where Cost Quietly Explodes (or Shrinks)

If there is one area where factories can really help buyers, it’s packaging.

Packaging affects more than unit cost

Packaging impacts:

Manual packing time

Carton size

Container loading

Shipping cost per unit

A beautiful retail box may cost:

+$0.10 in packaging

+$0.30 in shipping

Is it wrong? Not necessarily.

But it must be intentional.

The hidden MOQ of packaging

Many buyers are surprised to hear:

“The product MOQ is OK, but the packaging MOQ is higher.”

This is normal.

Printing factories also have:

Minimum runs

Setup costs

Ignoring this early often causes last-minute changes — and delays.

How Experienced Buyers Keep Costs Under Control

From real projects, the buyers who succeed usually:

Start with existing molds

Keep first packaging simple

Launch, test, then upgrade

Increase MOQ step by step

Very few successful pet brands started with:

“Fully custom everything from day one.”

They earned that stage.

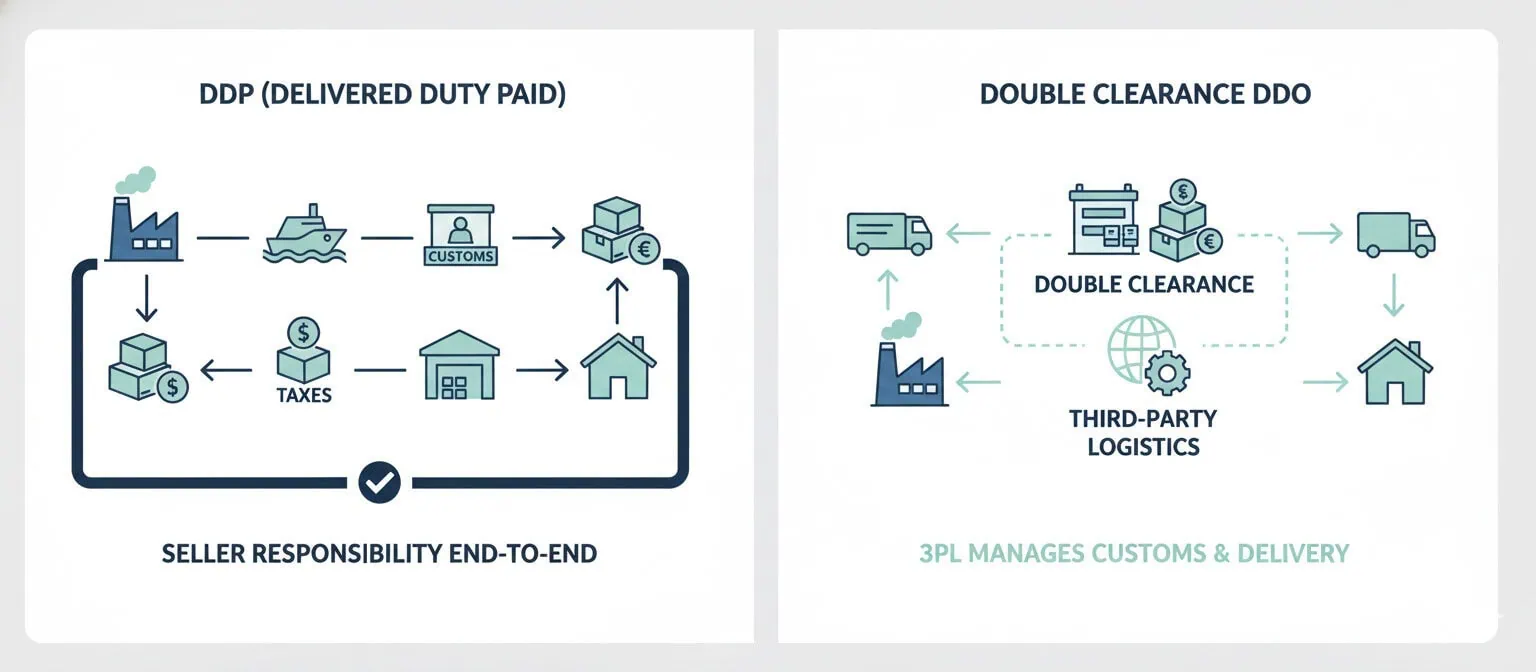

What a Good OEM Partner Actually Does

A good pet supplies manufacturer in China should not just send a number.

They should:

Explain what drives the cost

Show where you can save

Warn you where saving is risky

Help you choose, not push you

If a factory only says:

“This is the price, take it or leave it”

They are not thinking long-term.

Final Words (From the Sales Desk)

Here’s the honest truth:

Most buyers don’t lose money because the price is high.

They lose money because they optimize the wrong part of the cost.

Once you understand:

When mold fees make sense

How unit price really works

Why packaging decisions matter

Cost stops being a problem — and starts becoming a planning tool.

If you’re already discussing a custom project and want practical advice, not sales pressure, that’s exactly where we help.