Table of Contents

The global pet industry is expanding faster than ever, creating new opportunities for brands, distributors, importers, and e-commerce sellers. As competition increases, more companies are turning to OEM (Original Equipment Manufacturer) pet supplies manufacturing to build private-label product lines, reduce costs, expand assortment, and strengthen brand presence.

This comprehensive guide explains everything you need to know about OEM pet supplies manufacturing, how the process works, why global buyers choose China, and how OEM helps build a scalable and profitable pet brand.

1. What Is OEM Pet Supplies Manufacturing?

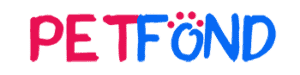

OEM (Original Equipment Manufacturer) pet supplies manufacturing refers to a business model where a factory produces pet products according to the buyer’s brand, specifications, design, and packaging requirements, while the final product is sold under the buyer’s own brand name.

In simple terms:

The factory manufactures the product

The buyer owns the brand

The finished goods carry the customer’s label and packaging

OEM manufacturing is widely used in industries such as electronics, household goods, textiles, cosmetics, and especially pet supplies, where product variety and customization demand are high.

2. What Types of Pet Products Can Be OEM Manufactured?

OEM manufacturing is extremely flexible, covering nearly every major pet product category. Some of the most commonly customized products include:

1. Dog Toys

TPR toys

Rubber toys

Rope toys

Plush toys

Squeaky toys

Chew toys

Interactive toys

2. Cat Toys

Feather toys

Cat teaser wands

Plush mice

Catnip toys

Spring toys

Ball toys

3. Collars, Harnesses, and Leashes

Nylon harnesses

Adjustable collars

Training leashes

Reflective walking gear

Set combinations

4. Pet Feeding Products

Plastic bowls

Stainless steel bowls

Silicone feeding mats

Foldable travel bowls

5. Pet Hygiene Products

Dog training pads

Pet wipes

Deodorizing sprays

Grooming brushes and tools

6. Cat Litter

Tofu litter

Bentonite litter

Mixed or functional litter formulations

7. Pet Food and Treats

Dry dog food

Wet cat food

Dog biscuits

Jerky pet treats

Freeze-dried snacks

Because OEM covers such a wide range of categories, global retailers and online sellers can build large private label assortments without owning a factory.

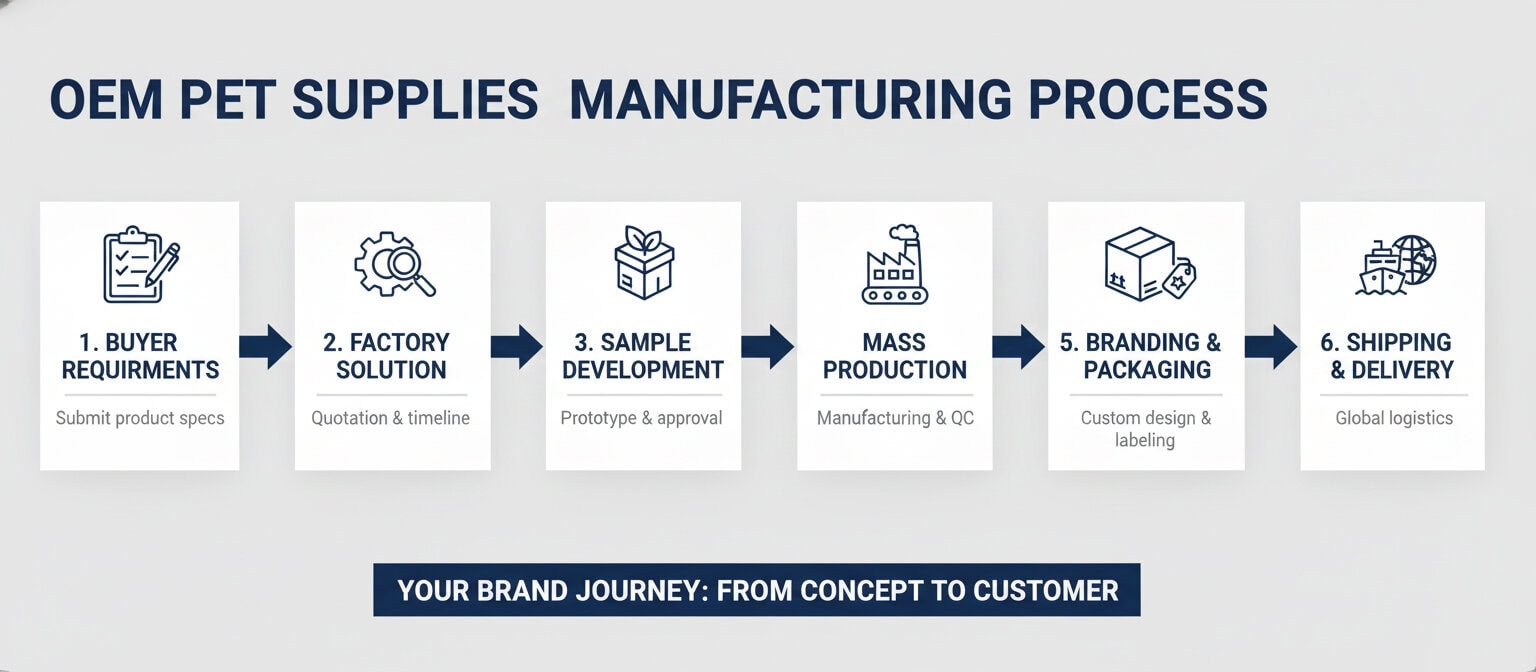

3. How Does the OEM Manufacturing Process Work?

The OEM process is structured, predictable, and designed to support scalable production. A standard OEM project follows these steps:

Step 1: Buyer Provides Requirements

The buyer submits:

Product category

Material choice

Size and specifications

Target pricing

Custom colors

Packaging requirements

Branding details (logos, barcodes, design style)

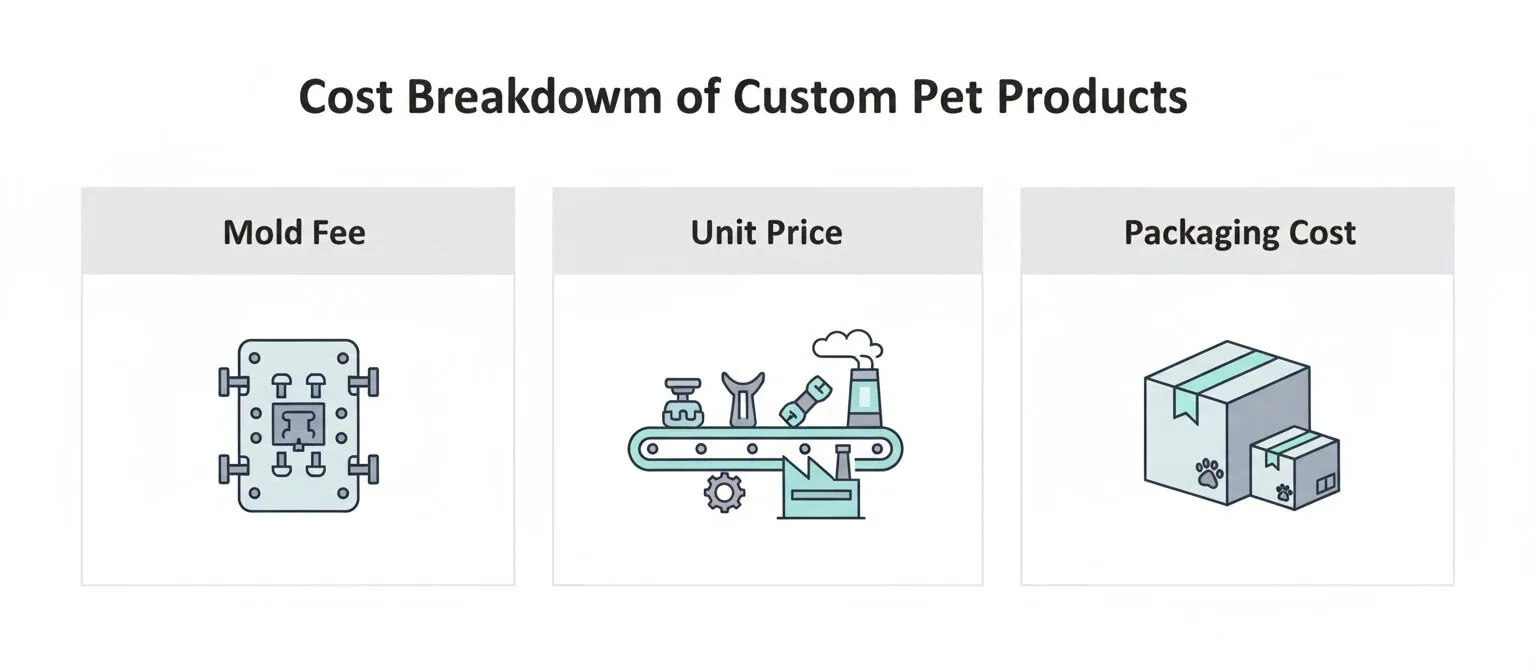

Step 2: Factory Provides a Manufacturing Solution

A professional OEM manufacturer offers:

Material recommendations

Engineering suggestions

Packaging options

Pricing breakdown

Production timeline

MOQ (Minimum Order Quantity) requirements

This step ensures the project is feasible and aligned with market needs.

Step 3: Sample Development

The factory creates:

Product prototype

Material samples

Packaging samples

Color variations

The buyer checks:

Quality

Functionality

Appearance

Branding accuracy

Only after sample approval does mass production begin.

Step 4: Mass Production

This stage includes:

Raw material sourcing

Large-scale manufacturing

Injection molding (for TPR or plastic toys)

Stitching and sewing (for textile products)

Automated production (for pads, wipes, litter)

Quality control checks

Packaging and labeling

OEM factories maintain strict QC procedures to ensure consistency.

Step 5: Branding & Packaging

The factory applies the customer’s brand identity:

Logo printing

Hangtags

Header cards

OPP bags

Retail gift boxes

UPC/EAN barcode stickers

This is where a product transforms from a generic item into a complete private-label brand asset.

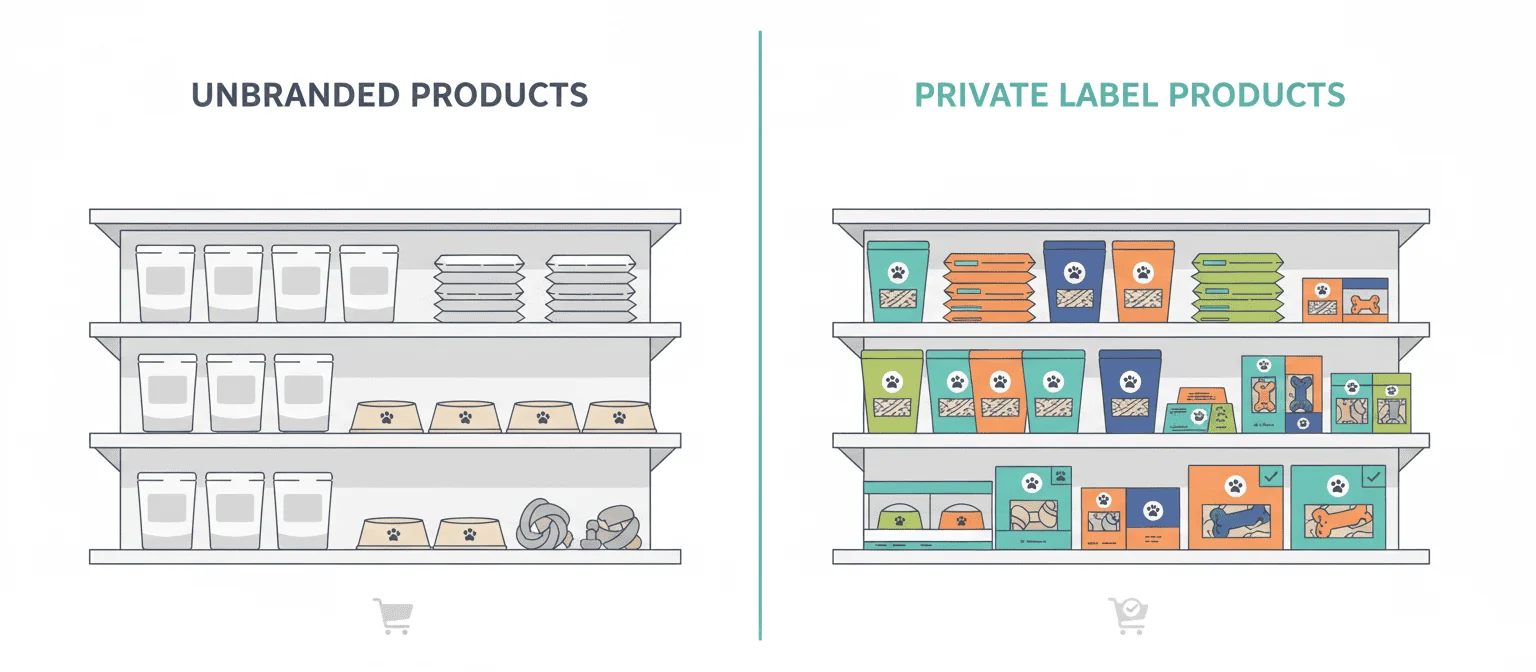

Step 6: Shipping & Logistics

The factory prepares:

Export cartons

Palletization

Customs documentation

The buyer may choose:

FOB shipping from Chinese ports

CIF

DDP delivery to destination warehouses

4. OEM vs. ODM: What’s the Difference?

Many buyers confuse OEM with ODM. Here’s the difference:

Feature OEM ODM

Who designs the product? Buyer Factory

Who owns the brand? Buyer Buyer

Customization level Medium–High Medium

Speed to launch Fast Very fast

Ideal for Private label brands Buyers who want ready-made products

OEM = your idea + factory production

ODM = factory idea + your brand

Most global brands use both models depending on the project.

5. Why Do Global Pet Brands Choose China for OEM Manufacturing?

China is the global center of pet product manufacturing due to several advantages:

1. Strong Industrial Clusters

Different regions specialize in different products:

Taizhou: TPR toys, plastic injection molding

Dongguan / Guangzhou: textile pet products

Shandong / Shanghai: pet food & treats

Qingdao / Hebei: cat litter and hygiene products

These clusters ensure efficiency, stable quality, and economies of scale.

2. Mature OEM/ODM Capabilities

Chinese factories offer:

Fast sampling

Advanced engineering

Strong mold development capacity

Competitive pricing

Full packaging customization

3. International Certifications

Most top factories hold:

ISO quality systems

BSCI / Sedex audits

FDA / HACCP (for food)

CE / EN71 / ASTM

REACH / RoHS compliance

4. Competitive Pricing

China’s supply chain scale allows for:

Lower material cost

Efficient labor structure

Large-volume production

Making Chinese OEM ideal for private-label brands.

5. Wide Product Range

Buyers can source all categories from a single ecosystem.

6. Benefits of OEM Pet Supplies Manufacturing

OEM offers unparalleled advantages:

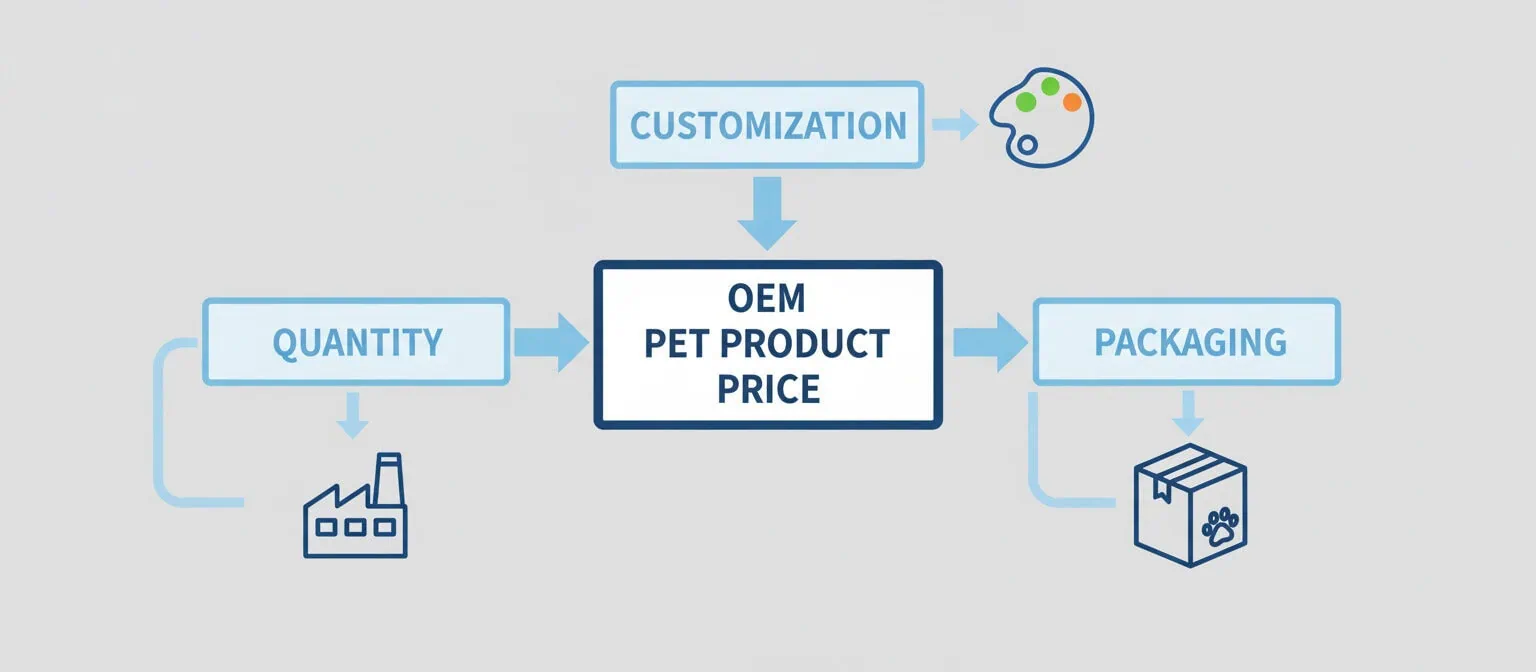

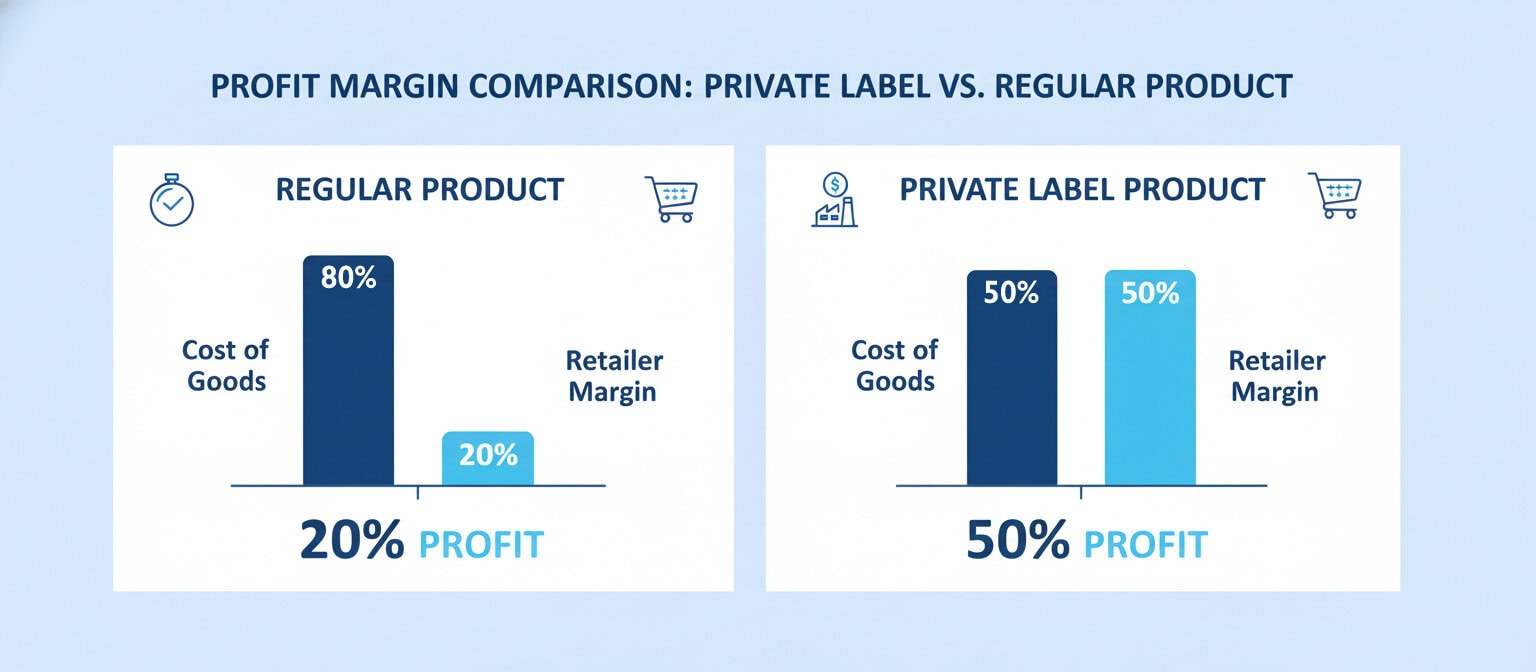

1. Higher Profit Margins

Custom products avoid price wars and allow premium pricing.

2. Strong Brand Identity

You build brand loyalty instead of promoting someone else’s brand.

3. Product Exclusivity

Competitors cannot sell the same product with the same packaging.

4. Market Adaptation

Products can be customized for:

Size

Color

Packaging language

Cultural preferences

5. Stable Supply Chain

The factory produces exclusively for your brand, reducing stock-out risks.

6. Better Marketing Performance

Custom packaging performs better on:

Amazon listings

Retail shelves

Social media

Influencer campaigns

7. Faster Expansion

Easily scale from 10 → 100 → 300 SKUs.

7. Example: How a Professional OEM Factory Like Petfond Works

Petfond, based in Taizhou, specializes in:

TPR dog toys

Injection-molded pet products

Silicone items

Grooming accessories

Seasonal gift sets

Complete private-label packaging solutions

Why international brands choose Petfond:

Strong material expertise

Fast sample turnaround

Low and flexible MOQ

Professional design support

Strict quality control

Export experience to 30+ countries

Petfond represents the new generation of OEM factories—professional, flexible, and brand-oriented.

8. How to Choose a Reliable OEM Pet Product Manufacturer

Look for:

Certification readiness

Strong communication

Sample quality

Transparent pricing

Reasonable MOQs

Factory photos/videos

Experience with foreign brands

9. Conclusion: OEM Manufacturing Is the Future of Pet Brands

OEM pet supplies manufacturing enables:

Higher profits

Stable supply

Fast category expansion

Stronger branding

Global competitiveness

Whether you’re an importer, retailer, or pet brand, OEM manufacturing is one of the most effective strategies to build a sustainable long-term business.