Table of Contents

Let me be very honest with you.

If you are looking for a fixed price list, you are probably still thinking in a trading company or distributor mindset.

And that’s not wrong.

It’s just not how OEM pet supplies manufacturing actually works.

Almost every week, we receive emails like these:

“Can you send me your price list?”

“What is your MOQ?”

“I just need a rough price to compare.”

These questions are completely reasonable.

But when you work directly with a pet supplies factory in China, a fixed price list usually creates more confusion, not clarity.

Let me explain why — the same way we explain it to our real customers.

First, let’s be clear: we are not avoiding prices

Some buyers assume that when a factory says “we don’t have a price list”, it means:

the supplier is hiding something

prices are unstable

negotiation will be difficult

In reality, it’s the opposite.

Factories that work seriously with OEM buyers cannot give one price without knowing the order details, because that price would be meaningless.

Not higher.

Not lower.

Just meaningless.

Why “one price” does not exist in pet supplies manufacturing

When buyers ask for a price list, what they usually imagine is something like this:

Product A – $X

Product B – $Y

MOQ – same for everything

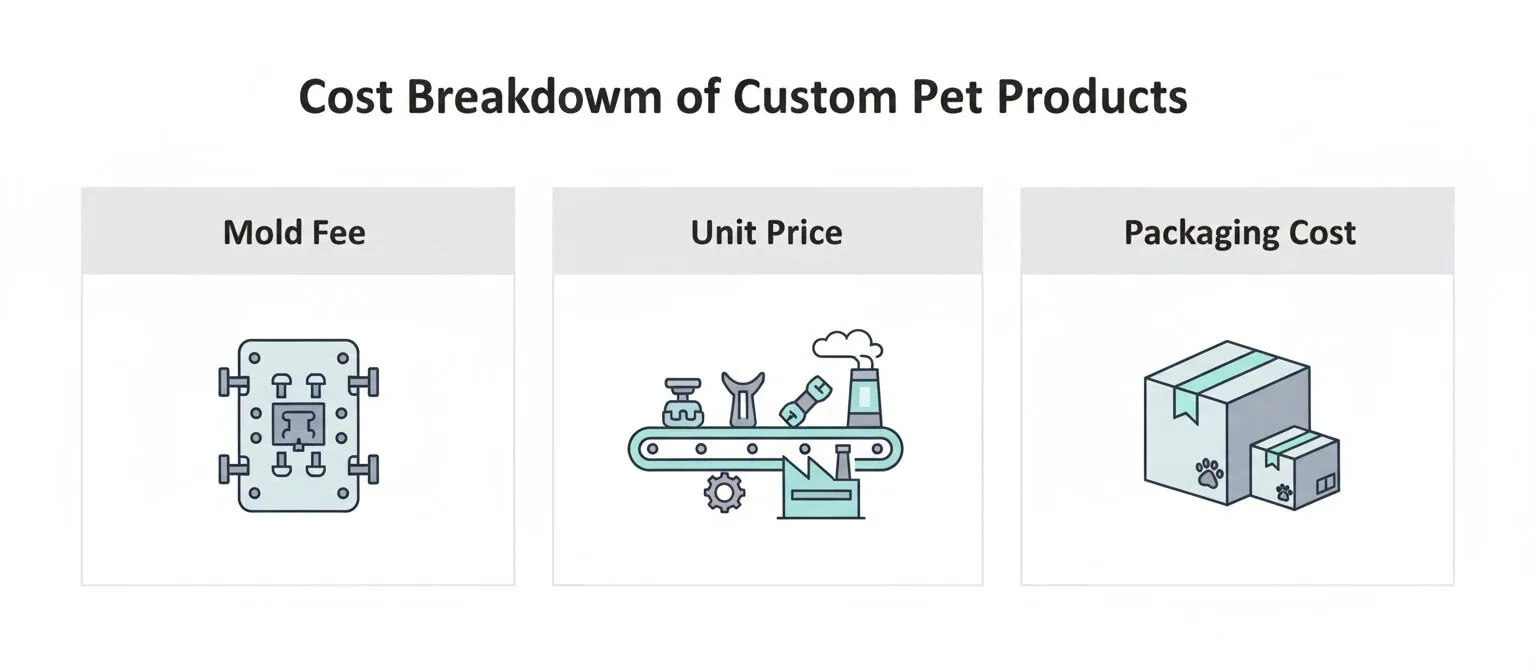

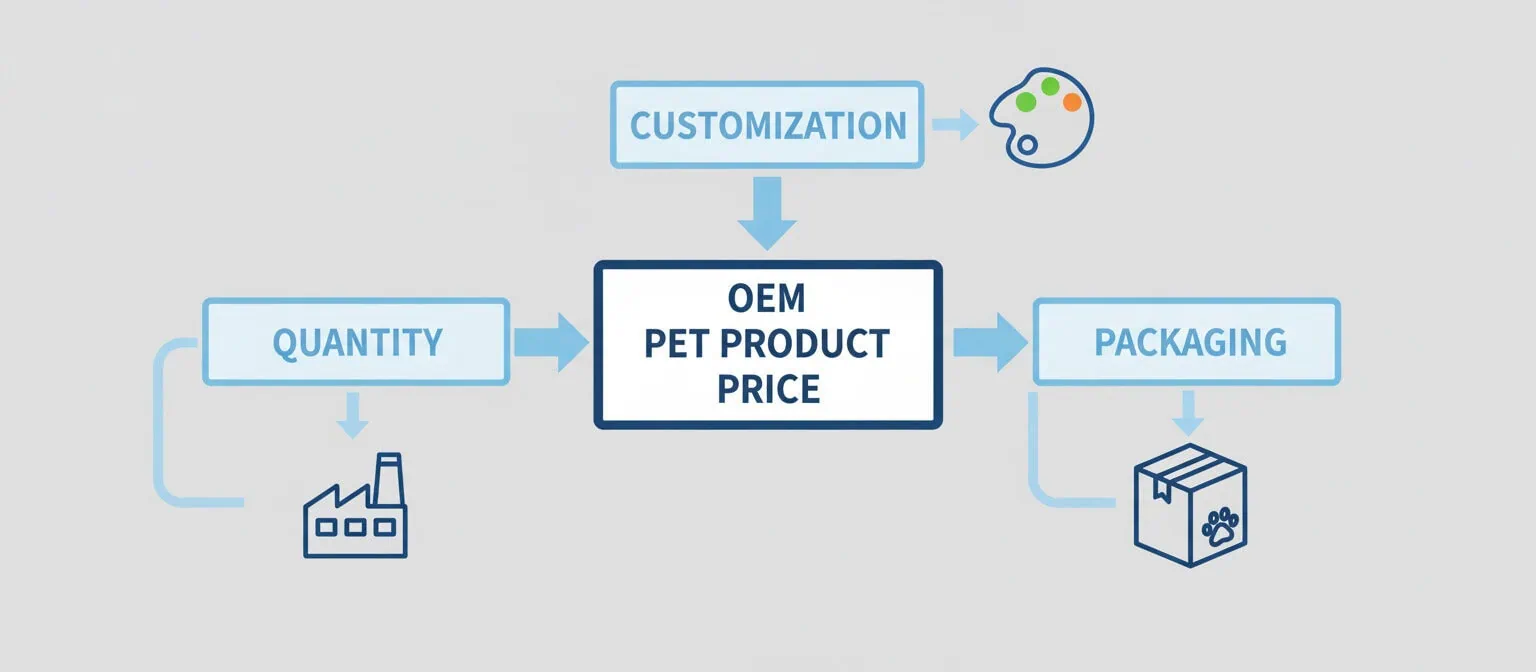

But in real manufacturing, three things always change the price, even for the same product.

1. Quantity

2. Customization

3. Packaging

If any one of these changes, the price changes.

That’s not a sales rule.

That’s a production reality.

Let’s talk about MOQ — because this is where most misunderstandings start

When buyers ask about MOQ, what they usually mean is:

“What is the smallest order you are willing to accept?”

But for factories, MOQ is not a sales decision.

MOQ is the minimum level where production becomes stable.

A silicone lick mat, a TPR dog toy, and a stainless steel pet bowl are all “pet products”, but:

they use different materials

different machines

different workers

different production rhythms

So naturally, they have different MOQs.

This is why asking for “one MOQ number for all products” never works with OEM factories.

Why price always depends on quantity (even for the same product)

Let’s use a very simple example.

Imagine the same dog toy:

same mold

same material

same packaging

If you order:

500 pcs

5,000 pcs

Do you expect the unit price to be the same?

Of course not.

At lower quantities:

raw materials are bought in smaller volumes

machine setup cost is spread over fewer units

labor efficiency is lower

At higher quantities:

material cost goes down

production becomes smoother

waste rate is lower

This is why quantity is always the first thing a factory needs before quoting.

Customization changes more than buyers expect

Many buyers say:

“It’s the same product, just add my logo.”

From a marketing perspective, that sounds small.

From a factory perspective, that may involve:

new printing setup

color matching

packaging redesign

additional quality checks

Sometimes customization has a very small cost impact.

Sometimes it changes the entire production plan.

Without knowing your customization level, any price would just be a guess.

Packaging is part of the cost — not an afterthought

This is another area where price lists fail completely.

Packaging affects:

unit cost

MOQ

carton size

shipping cost

For example:

bulk OPP bag vs retail color box

simple label vs full branding

single SKU carton vs mixed SKUs

Two buyers ordering the same product but with different packaging will never receive the same quotation.

So how does a real quotation actually work?

Here is what we normally do with serious buyers.

We start with context.

We need to know:

Which products you are interested in

Whether you want customization

Rough quantity per item

Your target market (EU / USA / others)

With this information, we can:

confirm realistic MOQ

calculate executable pricing

suggest better options if needed

This is how you get a price you can actually use.

Why this approach is better for buyers (even if it feels slower)

A fixed price list feels fast.

A proper quotation saves time later.

Because:

prices match your real order

MOQs are realistic

production issues are discovered early

Most failed sourcing projects don’t fail because of price.

They fail because assumptions were wrong.

A very common mistake buyers make

Some buyers collect 10 “price lists”, compare numbers, and choose the lowest one.

Later, they find out:

MOQ cannot be met

packaging is different

quality level is not the same

delivery time was unrealistic

At that point, the cheapest price is no longer cheap.

What we actually do as an OEM pet supplies manufacturer

Our job is not just to quote.

Our job is to help buyers:

understand production limits

control cost realistically

avoid sourcing mistakes

build products that can actually ship

This is why we don’t send price lists.

We send solutions that work in real production.

If you want a price that makes sense, here’s what to do

If you are serious about sourcing pet products from China, the fastest way forward is simple:

Select the products you like

Tell us what level of customization you need

Share your estimated quantity

We will then tell you:

what the MOQ really is

what the price really means

whether the project is realistic

No guessing.

No generic numbers.

Just a quotation that matches reality.

Final words

Factories don’t avoid price lists because they are complicated.

They avoid them because real manufacturing is specific.

Once you understand this, sourcing pet supplies becomes much easier — and much more predictable.

If you are looking for a pet supplies manufacturer in China that communicates clearly and quotes responsibly, you are welcome to contact our team.