The pet care industry has witnessed a significant rise in demand for high-quality products, and cat litter boxes are no exception. As more pet owners prioritize hygiene, comfort, and durability, manufacturers are seeking materials that not only meet these needs but also stand the test of time. This shift has introduced premium polypropylene (PP) plastic as a standout material in the production of cat litter boxes. With its unique blend of strength, flexibility, and environmental benefits, premium PP plastic is rapidly becoming the preferred choice for manufacturers.

Table of Contents

Understanding PP Plastic

What is PP (Polypropylene) Plastic?

Polypropylene, commonly referred to as PP, is a thermoplastic polymer known for its versatility. First synthesized in the 1950s, PP plastic has since evolved into one of the most widely used plastics due to its adaptable nature. It is lightweight, durable, and resistant to many chemical solvents, acids, and bases, making it suitable for a variety of applications, from packaging to automotive components and, most recently, pet products like cat litter boxes.

Key Properties of PP Plastic

PP plastic possesses several key characteristics that make it an ideal material for cat litter box production. It is resistant to cracking under stress, highly durable, and offers excellent chemical and heat resistance. Additionally, it is lightweight, moldable, and capable of retaining its structure over time, even with constant exposure to moisture and wastes.

Why PP Plastic Stands Out in Manufacturing

Manufacturers gravitate toward PP plastic because of its ease of production and processing efficiency. Unlike other materials, PP plastic can be molded into complex shapes and structures without compromising its integrity. This not only reduces production time but also minimizes material waste, making it a cost-effective solution.

The Importance of Material Selection in Cat Litter Boxes

Stainless steel cat litter box

Wooden cat litter box

Cardboard cat litter box

How Material Choice Impacts Product Performance

The material used in cat litter boxes plays a crucial role in determining the product’s overall performance. Inferior materials can crack, absorb odors, and harbor bacteria, creating unsanitary conditions for both pets and owners. A carefully chosen material ensures durability, ease of cleaning, and resistance to the daily wear and tear imposed by frequent use.

Common Materials Used in Cat Litter Box Production

Historically, cat litter boxes have been manufactured using a range of materials, including lower-grade plastics, metals, and even wood. While these materials offer some advantages, they fall short in areas such as odor control, longevity, and ease of manufacturing. For instance, metal may corrode over time, while wood can absorb moisture and deteriorate.

Challenges with Other Materials

Other materials often present challenges such as warping, bacterial growth, and difficulty in cleaning. Lower-quality plastics, for example, tend to crack faster, leading to product failure. Metal litter boxes may be sturdy, but they are heavier and more prone to rusting, making them impractical for long-term use.

Why Premium PP Plastic is the best choice

Superior Durability and Strength of Premium PP Plastic

Premium PP plastic offers superior strength and durability compared to other materials. It withstands the repeated actions of scooping, cleaning, and cat movements without losing its structural integrity. This resilience ensures that litter boxes made from premium PP plastic have a much longer lifespan than those made from other materials.

Long-Term Cost-Effectiveness for Manufacturers

PP plastic is a common raw material. Due to its large output, manufacturers can purchase PP plastic at a relatively low price. Moreover, when PP plastic is used to produce cat litter boxes, its defective rate is stable. When the injection molding machine works well, the defective rate can be reduced to negligible.

PP Plastic's Impact on Cat Comfort and Health

Non-Toxic and Pet-Safe Properties of PP Plastic

PP plastic is non-toxic, making it safe for pets. This is especially important for cats, who may come into frequent contact with the litter box material. The inert nature of PP plastic ensures that no harmful chemicals are released, contributing to a healthier environment for cats.

In fact, the properties of PP plastic are sufficient to make it used to produce human food utensils, so it can ensure the health and safety of pets for 100% sure.

How PP Plastic Reduces Bacterial Growth

The smooth surface of PP plastic naturally resists bacterial buildup, a critical feature in maintaining hygiene. Bacteria and mold often thrive in porous materials, but PP plastic’s non-porous nature prevents these microorganisms from embedding themselves into the surface, helping to keep the litter box cleaner for longer periods.

Odor Resistance for a Cleaner Environment

Odor control is one of the top concerns for cat owners. PP plastic is highly resistant to absorbing odors, keeping unpleasant smells from lingering. This ensures a more pleasant environment for both cats and their owners, without the need for constant scrubbing or deodorizing.

Environmental Benefits of Using PP Plastic

Eco-Friendly Aspects of Premium PP Plastic

PP plastic is eco-friendly in multiple ways. Its durability means that products last longer, reducing waste. Furthermore, it can be recycled multiple times, contributing to a circular economy. For manufacturers focused on sustainability, premium PP plastic offers a responsible choice that minimizes environmental impact.

PP Plastic Recyclability and Sustainability in Manufacturing

Although we do not use recycled PP plastic to produce cat litter boxes.

The recyclability of PP plastic sets it apart from many other plastics. Litter boxes made from PP plastic can be easily recycled at the end of their life cycle, reducing the need for virgin materials and contributing to resource conservation.

Reducing Environmental Impact with PP-Based Products

By using PP plastic in cat litter box production, manufacturers help to reduce the overall carbon footprint of their products. Its lightweight nature reduces transportation emissions, while its ability to be recycled cuts down on landfill waste.

Design Flexibility with Premium PP Plastic

Molding Versatility

Aesthetic Appeal

Branding possibilities

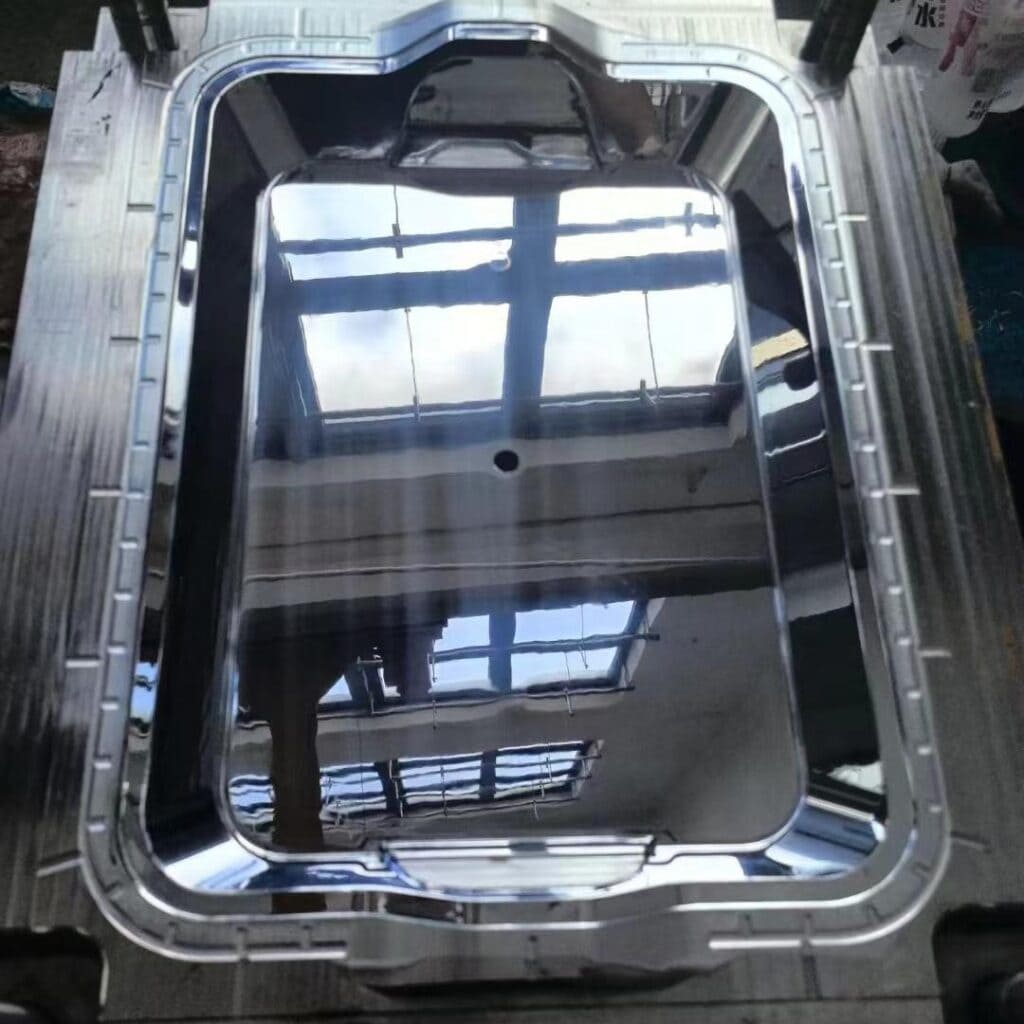

Molding Versatility for Innovative Designs

PP plastic offers unparalleled design flexibility. It can be molded into a wide range of shapes and sizes, allowing manufacturers to create litter boxes that cater to varying preferences. Whether it’s a sleek, modern design or a functional, space-saving model, PP plastic enables endless possibilities.

Creating Lightweight Yet Sturdy Products

PP plastic’s combination of lightness and strength makes it ideal for products that need to be both durable and easy to handle. This balance is particularly beneficial for litter boxes, which need to withstand the weight of litter and frequent movement but remain portable for consumers.

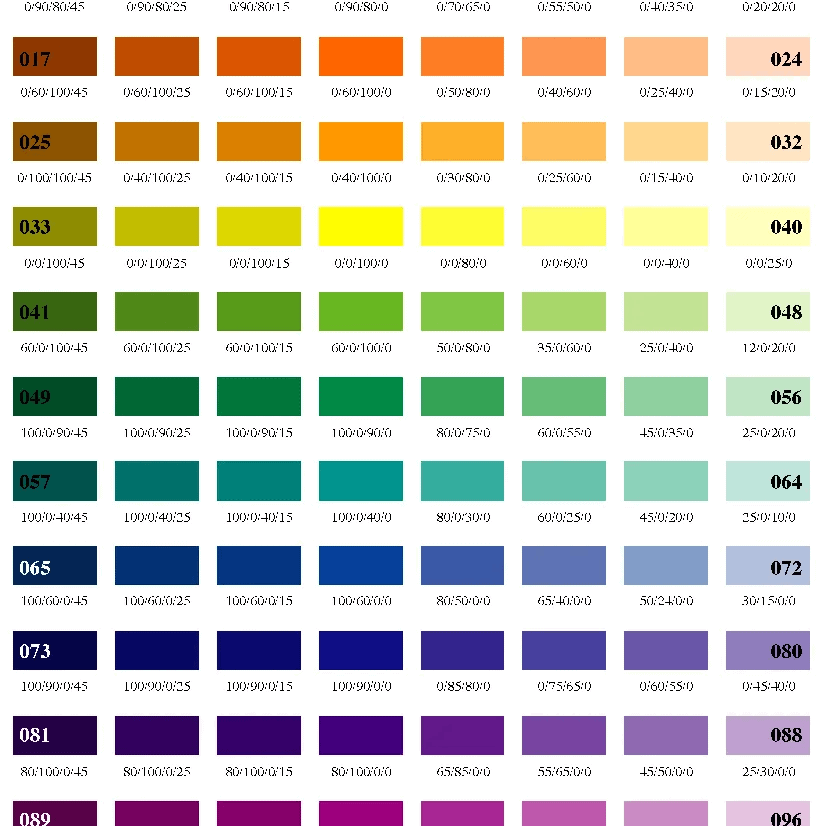

How PP Plastic Enhances Aesthetic Appeal

Beyond its functional advantages, PP plastic also offers aesthetic benefits. It can be produced in a variety of colors and finishes, allowing manufacturers to create visually appealing products that blend seamlessly into modern home decor.

Branding Possibilities with Premium PP Plastic

For manufacturers, premium PP plastic offers excellent branding opportunities. Logos and design elements can be seamlessly integrated into the product, enhancing brand visibility and consumer engagement.

Cost Efficiency in Manufacturing with Premium PP Plastic

Reduced material wastage

Lower production cost

Lower Production Costs with PP Plastic

PP plastic’s ability to be easily molded and processed reduces production time and costs. Manufacturers can produce high-quality litter boxes with fewer resources, making it an economical choice for large-scale production.

Reduced Material Wastage During Manufacturing

With PP plastic, manufacturers experience less material wastage. Its malleability ensures that excess material can be minimized during the molding process, leading to more efficient use of resources.

Energy Efficiency in the Production Process

The production process for PP plastic is highly energy-efficient, requiring less energy than other materials. This translates into lower operational costs and a reduced environmental footprint.

Safety Standards and Compliance with PP Plastic

Meeting Industry Safety Standards with Premium PP Plastic

Premium PP plastic complies with stringent industry safety standards, ensuring that products are safe for both pets and their owners. These standards include non-toxic production processes and the absence of harmful chemicals.

Ensuring Non-Toxic Production Processes

PP plastic is produced using non-toxic materials, ensuring that the final product is safe for pets. This is particularly important for litter boxes, where cats are in close contact with the material on a daily basis.

Certifications and Approvals for PP Plastic Products

Many manufacturers using premium PP plastic obtain certifications from regulatory bodies, ensuring that their products meet high safety and quality standards. These certifications offer additional assurance to consumers.

Heat and Chemical Resistance of PP Plastic

Why Heat-Resistant Properties Matter for Litter Boxes

PP plastic’s ability to withstand high temperatures ensures that it remains stable even in harsh environments. This is especially important for litter boxes, which may be cleaned with hot water or exposed to heat in certain conditions.

PP Plastic’s Chemical Resistance and Its Advantages

Premium PP plastic is resistant to a wide range of chemicals, ensuring that cleaning agents do not degrade the material. This resistance helps maintain the integrity and appearance of the litter box over time.

Real-Life Examples of PP Plastic's Performance in Extreme Conditions

PP plastic has been tested in extreme conditions, from chemical exposure to high heat. In every case, it has shown remarkable resilience, making it a trustworthy material for demanding environments.

Waterproof and Leak-Proof Capabilities

Why Waterproof Properties Are Crucial in Litter Boxes

A litter box needs to be waterproof to prevent leaks and spills that could damage flooring or furniture. PP plastic’s waterproof nature ensures that the litter box remains sealed and leak-free, even with heavy use.

How Premium PP Plastic Prevents Leaks and Spills

The seamless construction of PP plastic litter boxes prevents any leaks from occurring, keeping the surrounding area clean and dry. This feature is crucial for maintaining a hygienic environment.

Ensuring a Cleaner Environment for Pets and Owners

By preventing leaks and spills, PP plastic litter boxes contribute to a cleaner, healthier living space for both pets and their owners. This is especially important in multi-cat households, where cleanliness is paramount.

Contact us and get an instant quote for cat litter boxes!

-500x500.jpg)